Functional and Precise Wheel Load Scales

A wheel load scale consists of at least two platform-like weighbridges, which can either be operated stationary or as a mobile and handy version. The stationary wheel load scales (sometimes also called vehicle scales) can be placed either above ground (e.g., as ramps) or embedded in the ground. When only two platforms are used, each axle is measured individually, and the data is subsequently added up to obtain a total value. Alternatively, a weighing terminal can be connected, which automatically sums up the two weighing values. Mobile wheel load scales can connect up to 16 weighbridges at the same height. They are ideal for loading and unloading control and can also be used to check for possible overloading.

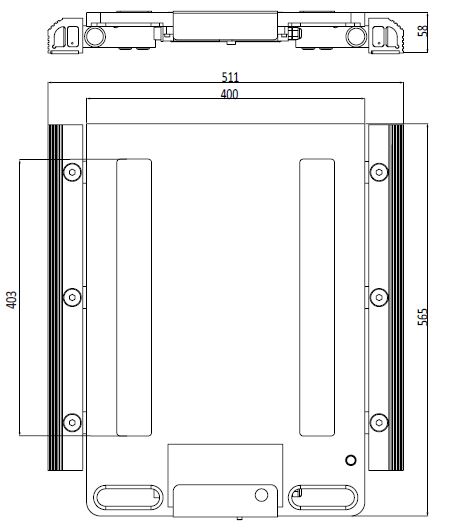

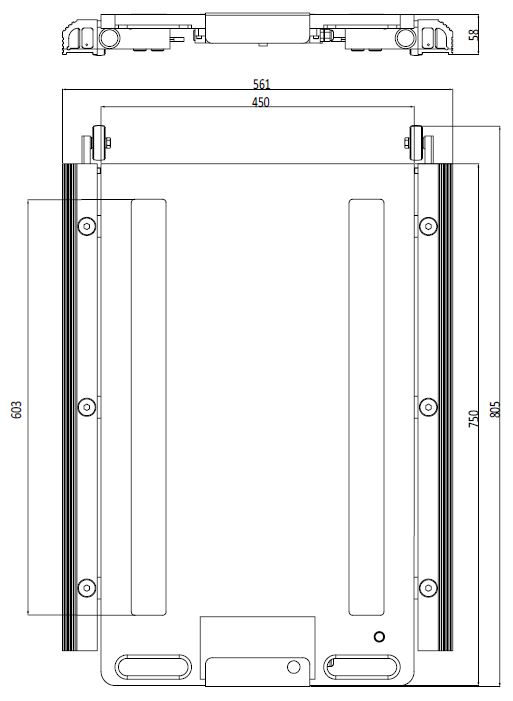

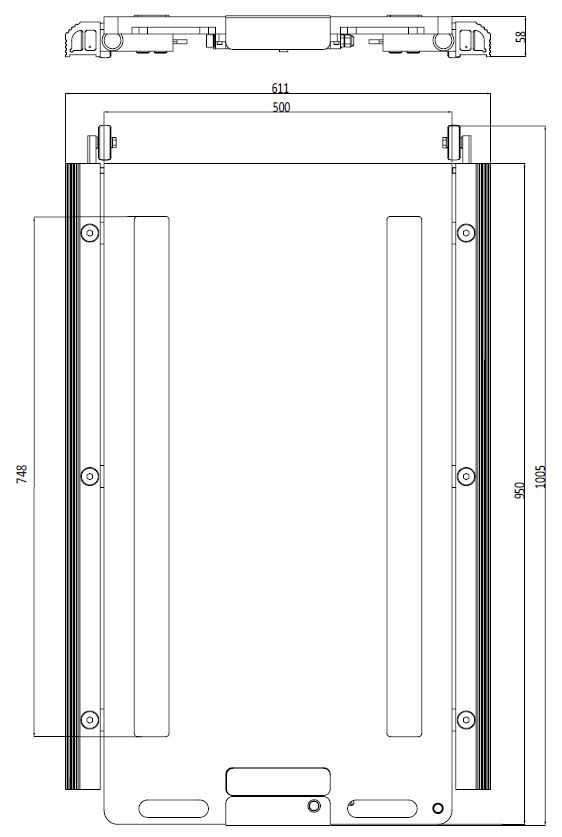

Various platform sizes are available:

Wheel Load Scale

RWS | Wheel Load Scale

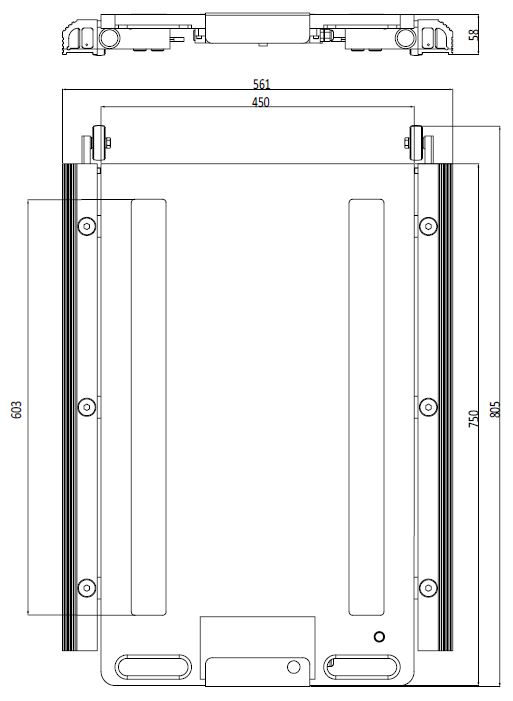

RWM | Wheel Load Scale

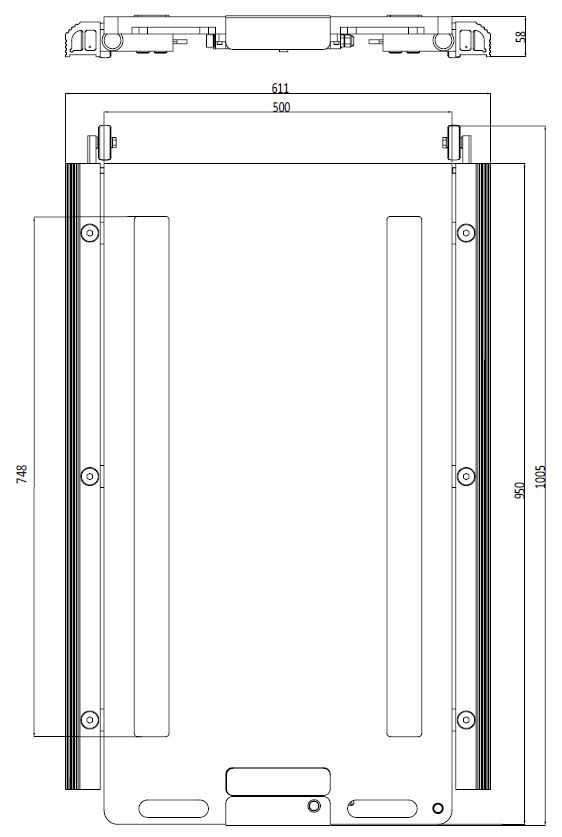

RWL |

|---|

|

|

|

400 x 565 mm

1,500 - 15,000 kg |

450 x 750 mm

6,000 - 15,000 kg |

500 x 950 mm

6,000 - 20,000 kg |

| |

|

|

All measurements in mm | Technical changes reserved

Measurement method

There are generally two different measurement methods for determining axle load with a wheel load scale: dynamic and static wheel load weighing. In the first method, the vehicle passes over the weighbridges at a constantly low speed of up to 5 km/h for weight determination. In the static method, on the other hand, the vehicle's wheels are precisely positioned on the weighbridges of the wheel load scale, i.e., within the centering bands. The driver then releases the brake and turns off the engine. Now, the wheel load of the motor vehicle can be measured while stationary. For both methods, it is not recommended to measure vehicles with nearly or completely flat tires.

Optimal Weighing Conditions for the Wheel Load Scale

For safe and accurate weighing, not only should the weighing modules be tailored to the process, but also the ground. It is advisable to always choose a level support surface for the scale, with a hardness level of at least 100 kg/cm². Additionally, it is useful to install an adjusted height range in front of and behind the weighing platform, ideally twice as long as the longest vehicle to be measured. If you regularly measure semi-trailers, tank trucks, or construction vehicles with more than two axles, BOSCHE height modules are recommended. For the ground-level fixation of wheel load scales, we are happy to supply you with pit frames.

To evenly distribute the axle load, place each wheel on a weighing module of the wheel load scale. Then, adjust the height at the vehicle's shock absorbers so that the weights on the left and right front and left and right rear are equal. It's important to note that the wheel load balance is always done diagonally. This means that if more load is needed on the front left axle, the rear right shock absorber should be adjusted upwards.